However, the hardness of rice husks which contain silica has been a major obstacle and little of this equipment has been put to practical use. The Grind Mill is a device that grinds rice husks and solidifies them, turning rice husks, which have not been fully utilized until now, into a valuable resource.

How the Grind Mill works

The Grind Mill is a device that grinds rice husks, compresses them, and then heats them with a heater to solidify them. The raw material is 100% rice husk only. Using the Grind Mill, you can easily make rice husk briquettes (rod-shap ed solid fuel), curl briquettes (coil-shaped solid fuel), and ground rice husks.http://www.unido.or.jp/en/technology_db/2673/

Rice husk briquettes

The rice husk briquette is a hollow solid fuel, approximately 35 cm long and 5.5 cm in diameter, made by grinding rice husks, compressing and heating them. The raw material is 100% rice husk, and no adhesives are used to solidify it.

The rice husk briquette is a “carbon-neutral” biomass fuel that does not produce any new CO2 through combustion.

It is resistant to moisture, can be stored for long periods of time, and contains no nitrogen oxides or sulfur oxides in the exhaust during combustion. It is also characterized by its low moisture content (about 5.5%), which minimizes the generation of smoke.

The rice husk briquette is used as heating fuel for greenhouse houses, boiler fuel for hot bath facilities, emergency stockpile fuel for municipalities, and fuel for barbecues.

Curl chips

Curl chips, like rice husk briquettes, are a carbon-neutral rice husk solid fuel. They are compressed and molded into a spiral shape without heating, and have excellent ignitability.

For industrial application, they are expected to reduce CO2 emissions by co-firing with coal in coal-fired power plants and coal boilers, and feasibility studies are being conducted in Punjab, India and Soc Trang Province, Vietnam.

Ground rice husks

Ground rice husks are made by coarsely grinding rice husks. These have excellent water absorption and retention properties, making them ideal as bedding material for livestock. They can also be used as a seedling soil for paddy rice and gardening. They are also lighter in weight than regular soil, resulting in cost reduction.

Water purifer

This is a highly functional water purifier that uses a special activated carbon made from rice husks.

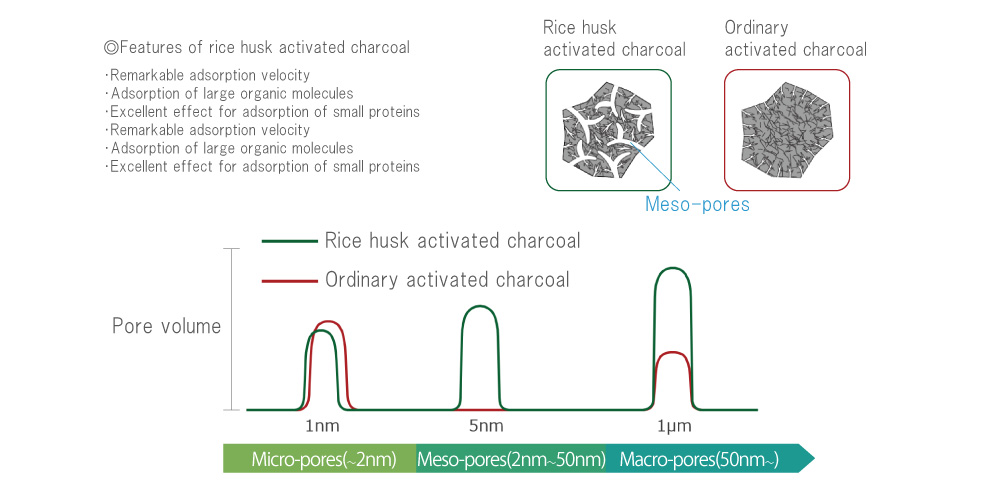

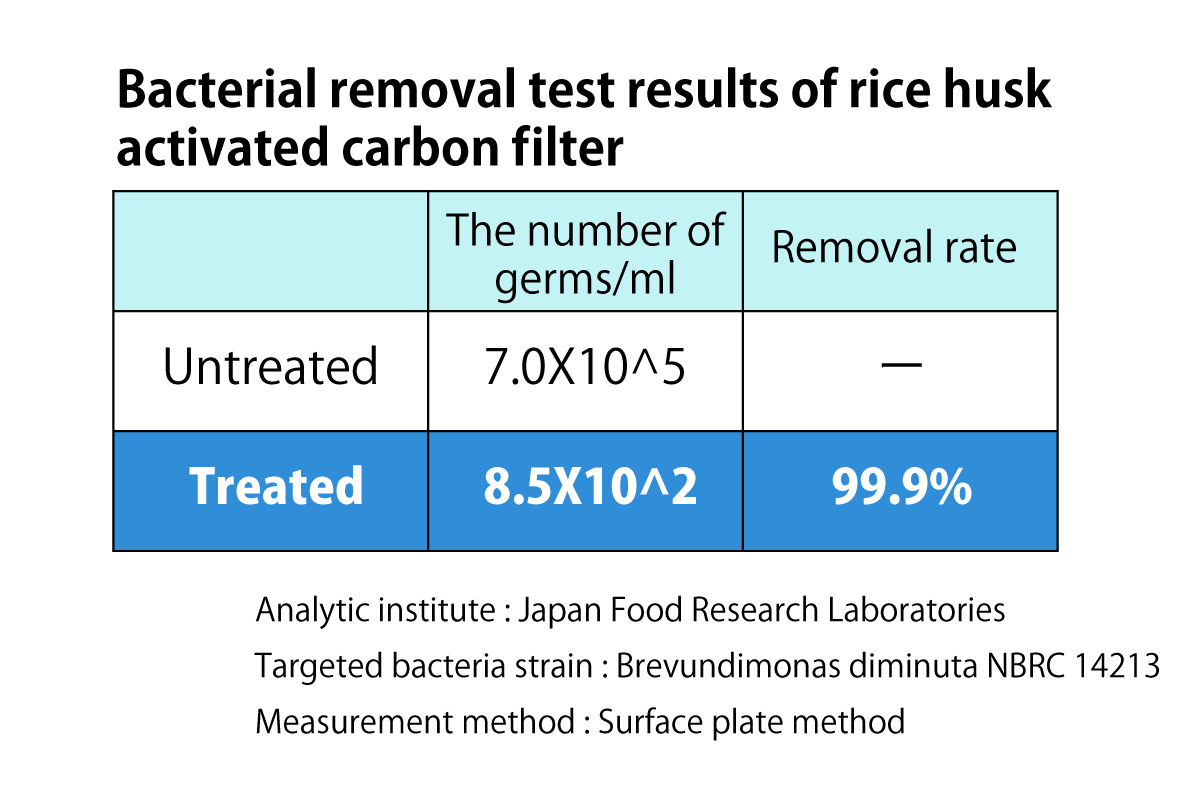

This rice husk activated carbon is a porous carbon material with three types of pores: micropores (~2nm), mesopores (2nm-50nm), and macropores (50nm-), which can adsorb and support minute substances, from small bacteria and proteins to large organic molecules. Rice husk activated carbon can remove 99.9% of bacteria, far exceeding the removal capacity of ordinary activated carbon.

Rice husk activated carbon can remove 99.9% of bacteria, far exceeding the removal capacity of ordinary activated carbon. Rice husks contain high levels of silica. Silica is an important mineral essential for beauty and health that makes up the entire body, including skin, hair and bones. Silica is expected to help regenerate and maintain collagen, prevent osteoporosis, and improve blood circulation. In particular, silicon derived from rice has been found to have a high absorption rate in the body.

Rice husks contain high levels of silica. Silica is an important mineral essential for beauty and health that makes up the entire body, including skin, hair and bones. Silica is expected to help regenerate and maintain collagen, prevent osteoporosis, and improve blood circulation. In particular, silicon derived from rice has been found to have a high absorption rate in the body.

The use of an activated charcoal filter made from rice husks can support the intake of silica.

For more information about the technology,please click here.